Your Content Goes Here

Briefly analyze the working principle of the high-voltage switch mechanical characteristic tester

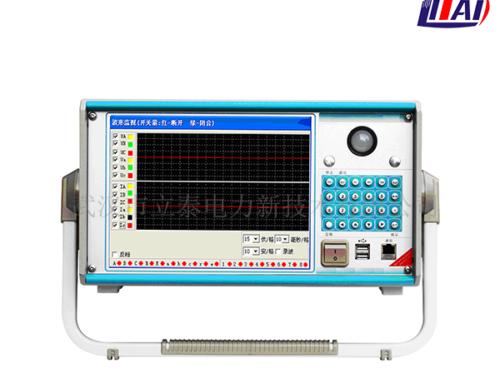

The switch mechanical characteristic tester produced by our company can be used in various voltage levels of vacuum, sulfur hexafluoride, less oil, more oil and other power systems.It also belongs to breaker dectecor. The measurement data is stable, the wiring is simple, and the operation is simple. It is a convenient product for high-voltage switch maintenance and testing. Here is a brief analysis of the working principle of the high-voltage switch mechanical characteristic tester.

Briefly analyze the working principle of the high-voltage switch mechanical characteristic tester as follows:

1. The imitated leakage current sent by the detector uses a step-down transformer to output low-voltage current.

The primary input voltage of a step-down output that mimics the leakage current is controlled by the potentiometer adjustment terminal, that is, through the potentiometer adjustment, the voltage of the input transformer primary is gradually increased from zero, and the secondary output of the transformer mimics the leakage current and is gradually increased. This can test the operating current characteristics of leakage maintenance.

The action current and time test of the leakage maintenance are controlled by the test button on the panel of the machine. When the test button is pressed, on the one hand, it outputs an imitating leakage current, and at the same time the electrical signal can trigger the chronograph millisecond, so when the leakage switch is activated After that, the time recorded is the operating time of the leakage maintenance switch when the leakage current is applied.

2. The machine’s panel is equipped with a machine power socket, fast-blow fuse, test line socket, power switch, adjustment knob, function switch, reset button, test button, and digital display milliamp meter, millisecond meter, etc.

Briefly analyze the working principle of the high-voltage switch mechanical characteristic tester. The zero-sequence transformer is not in the case of the leakage maintainer. The characteristic measurement of the maintainer 1. Preparation before the test Before connecting the tester to the power supply, the “power switch” of the instrument should be in the off position , The power supply should be connected to the power supply side of the leakage maintainer (AC220V), and the phase and neutral wires cannot be connected wrongly. The test line passes through the zero sequence transformer and then connects to the same phase line of the power supply of the tester. The function switch of the tester is placed in the “preset” position. After checking that the wiring is correct, turn the “current regulation” potentiometer on the panel of the tester counterclockwise to zero, and press the “power switch”. At this time, mA The indicator of the meter and millisecond meter should be zero, if it is not zero, just press the “reset” button.

3. The leakage current of the leakage maintainer itself or the leakage non-acting current measurement (the load side lead should be disassembled, and the function switch should be placed in the “preset” position. After the leakage maintainer is put in, press the test button at this time, clockwise slowly Adjust the “current regulation” potentiometer on the panel of the tester, the mA meter of the tester should show the mA value, and the current will gradually increase until the leakage protector is activated. At this time, the reading displayed by the mA meter is the leakage current. Action current.