Your Content Goes Here

Underground pipeline detector test principle: It also belongs to pipeline detector. The transmitter generates electromagnetic signals, and transmits the signals to the underground cable under test through different transmission connection methods. After the underground cable induces the electromagnetic signal, an induced current is generated on the cable, and the induced current runs along the cable. When the pipeline locator receiver detects on the ground, the electromagnetic wave signal will be received on the ground above the cable, and the electromagnetic wave will be received on the ground above the cable. The signal strength changes to determine the location and direction of the underground cable and the testing principle of the faulty underground pipeline detector.

The actual test is: the operator (person) combines the transmitter, receiver, optional accessories and metal pipeline (test target) in a certain environment (site) according to certain principles and theories, and uses a specific test method to combine the transmission The system test process from signal to detection signal and then to conclusion. In this process, no matter which link is used improperly, it may cause the failure of the test. That is to say (the actual test is) in the test system of personnel + underground pipeline detector + measured target + tested field factors, the operation of the underground pipeline detector is only an important link, and the metal pipeline structure, power supply method, wiring situation and laying Understanding of the environment and other factors is equally important, and the more you understand, the better the test results. I will not introduce the testing process of this set of underground pipeline detectors (you can contact customer service to provide information if necessary).

Transmitter principle

After connecting the cable, press the power switch, and the transmitter will start to work by pressing the OK button. The loop impedance is automatically detected to ensure that it is working in the best matching output state. When the icon in the lower right corner of the LCD starts to rotate to indicate the transmitter output signal, it indicates the transmitter It is working stably. At this time, observe the loop impedance value. Generally, 1Ω-3KΩ is appropriate. If it exceeds 3KΩ, it means that the impedance is too large and the signal in the line is very weak. It should be adjusted and improved from the following three aspects.

First, improve the grounding conditions of the grounding electrode, humidify or reconnect the system ground.

Second, ground the phase of the signal applied by the metal pipeline at the other end.

Third, adjust the frequency and change the low frequency when starting up to high frequency (Note: the high frequency is sufficient for testing metal pipelines by the direct connection method)

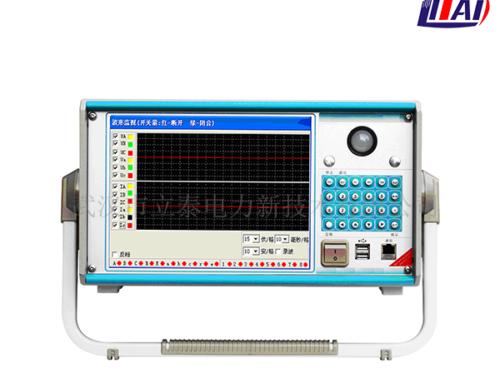

Receiver principle

Rotate the receiver on the axis of this point based on the current received signal strength (three-digit digital value), and the received signal will weaken with the rotation. When it is reduced to the weakest, the direction of the nose and the metal pipeline The direction of this point is at an angle of 90°. Continue to rotate the receiver, and the received signal will increase with the rotation. When the enhancement is the same as the reference value, the direction of the nose is the path direction of the metal pipeline, and the strongest signal is tracked forward along the direction of the nose. , The accurate path of the metal pipeline is detected. This process is signal tracking, and at the same time the path is detected.

Principles of locating fault points in the test of underground pipeline detector

There are many ways to lay cables, including those directly buried in the soil, some through pipes, and some are laid in trenches. No matter which way of laying, the test path and the depth of the side buried will not be affected, just use the same method. Completed, but the principle of fault detection and fault location location is different. It is not only affected by the method of burying, but also by the voltage level of the cable. Under normal circumstances, it is not recommended to use underground pipeline detectors to test faults for cables with voltage levels of 10kv and above. , And the 500v voltage level cable should give priority to the underground pipeline detector test failure. It is worth mentioning that the use of underground pipeline detectors to solve the 500v voltage level of directly buried cables, buried wires and street lamp circuit failures is the best choice.