Project Description

Product Features:

The whole set of device only consists of two parts: control box and voltage doubler, and the wiring is very simple.

Electronic control and tuning are adopted, which is convenient and comfortable to operate; voltage, current, etc. are directly read on the panel meter without conversion.

Perfect over-voltage and over-current protection function, and an external zinc oxide over-voltage protection device is foolproof.

With electronic voltage regulation, automatic polarization compensation and rich protection functions, the test operation is easier and safer; the use of intermediate frequency voltage doubler makes the test voltage more ideal, the test data is more accurate and stable, and the result is more reliable.One-minute timing and reminder function, set according to the requirements of the test procedure.

The test device for the leakage current tester for internal water-cooled generators is a new generation of LCD screen display and intelligent special test equipment developed by our company based on the principle of “low-voltage shielding” and the previous generation of products.It belongs to ac dc withstand voltage tester.

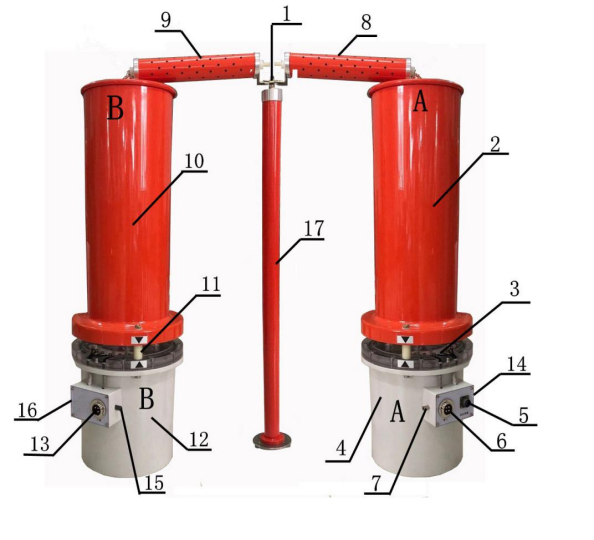

It adopts the core technology of high-power DC high-voltage generator, instead of traditional test transformers, high-voltage silicon stacks, stabilized capacitors, rectifier capacitors and inductors, DC high-voltage dividers, voltage regulators, mA meters, μA meters, and polarization A series of single-component combination test tools such as electric potential compensation device, which are all integrated into a high-voltage (generating) unit and a control box, significantly reduce the number of single components of the complete test device and greatly reduce the test equipment.

The weight of the tester reduces the work intensity of the test personnel, simplifies the test wiring, and makes the test more convenient, efficient and reliable. At the same time, it has electronic voltage regulation, automatic polarization compensation and rich protection functions, making the test operation easier and safer; the use of intermediate frequency voltage doubler makes the test voltage more ideal, the test data more accurate and stable, and the result more reliable.

The DC withstand voltage test and the DC leakage current test of the stator winding of the internal water-cooled generator are carried out under two conditions without external water blowing or water flow. The advantages and disadvantages of each are as follows:

1. Experiment with water blowing

Advantages: general DC high voltage tester can be used for testing (such as 60kV/10mA type), the equipment is light, easy to operate, accurate readings and not affected by water quality.

Disadvantages: Due to the structure of the generator unit, it is difficult to dry the water accumulated at the bottom. Therefore, it is very time-consuming, and the blowing time can even be more than a week. Extends downtime for major repairs. If the water is not completely blown, it will not only cause measurement errors, but also in case of arcing in the coil during the test, there is a danger of damaging the winding.

2. Test under water supply

Advantages: No water blowing equipment is needed, saving the time of blowing water.

Disadvantages: At present, AC test transformers (or resonance transformers) are combined with silicon stacks and capacitors, and additional devices are required to compensate for polarization of water collection pipes. The equipment is bulky, scattered, and wiring is complicated. The test result is affected by the water quality, the microammeter fluctuates greatly, and the reading is difficult.

| Specifications | 60/80 | 60/120 | 60/200 | 60/300 | 80/200 | 80/300 | 90/320 | 100/250 |

|---|---|---|---|---|---|---|---|---|

| Output voltage (kV) | 60 | 60 | 60 | 60 | 80 | 80 | 90 | 100 |

| Output current (mA) | 80 | 120 | 200 | 300 | 200 | 300 | 320 | 250 |

| Output power (kW) | 4.8 | 7.2 | 12 | 18 | 16 | 24 | 28.8 | 25 |

| Chassis weight (kg) | 17 | 33 | 35 | 38 | 38 | 39 | 36 | 40 |

| Double pressure weight (kg) | 18 | 10+24 | 10+24 | 14+37 | 15+36 | 15+37 | 14+25 | 17+38 |

| Height of pressure doubler (mm) | 630 | 730 | 730 | 900 | 900 | 900 | 850 | 1000 |

| Voltage measurement error | ≤1.0% (scale ±1 word) | |||||||

| Total current measurement error | ≤1.0% (scale ±1 word) | |||||||

| Leakage current measurement error | ±2.0% (full scale) | |||||||

| Overvoltage setting error | ≤1.0%; | |||||||

| Voltage stability | ≤1.0%; | |||||||

| Way of working | Rated load, continuous work for one time ≤ 5 minutes | |||||||

| Ambient temperature | -10℃~40℃ | |||||||

| Relative humidity | When the temperature is 25℃, no more than 90% (no condensation) | |||||||

| Altitude | Below 2000 meters | |||||||

| Ripple coefficient | ≤3.0% | |||||||

| Rated output power | Not less than 29kW | |||||||

| Hello Elena | ≤1.0% | |||||||

| voltage | Three-phase four-wire 50Hz 380V±10% | |||||||

| Chassis | 1 set |

|---|---|

| IF change | 2 units |

| Double pressure tube | 2 |

| One external zinc oxide overvoltage protection device | 1 |

| Current limiting resistor | 2 pcs |

| Power cable ≥5m, ≥45A root | 3 pieces |

| IF output cable ≥ 1.5m root | 3 pieces |

| High voltage lead ≥6m | 3 pieces |

| Discharge rod | 1 |

| Dedicated ground wire | 1 |

| Sink pipe sampling line ≥ 4m group | 3 pieces |

| Instruction manual | 1 set |

| experiment report | 1 copy |