Your Content Goes Here

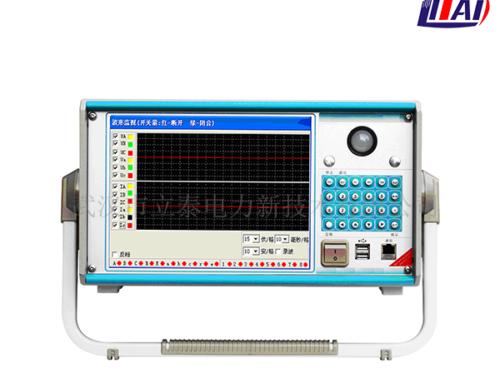

The DC resistance test developed by Litai Power can check the welding quality of the winding joints and whether the windings have inter-turn short circuits. It can detect whether the contacts of the voltage tap changer are in good contact and whether the actual position of the tap changer matches the indicated position. Whether the wire is broken, whether there are broken strands in the multi-strand wire winding, etc. What customers want to know most is the test and operation method of the DC resistance tester. The following takes the LTZR-100A DC resistance tester test and operation method as an example:

1. Test wiring of the DC resistance tester: Connect the tested product firmly to the terminal of the machine through the special test line, and connect the ground wire at the same time.

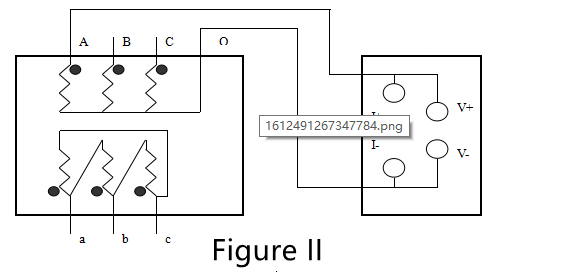

A. Direct measurement wiring, see Figure 2:

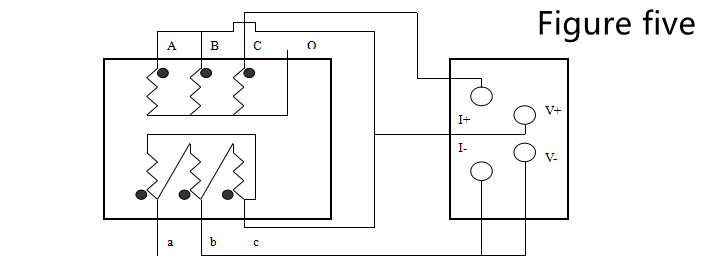

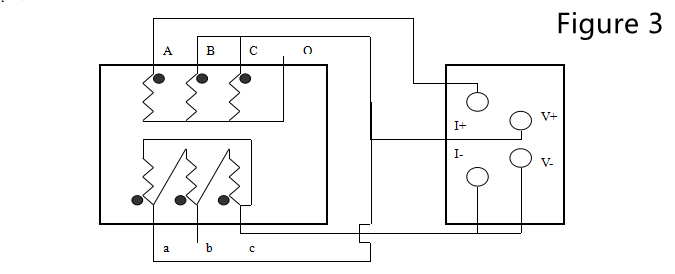

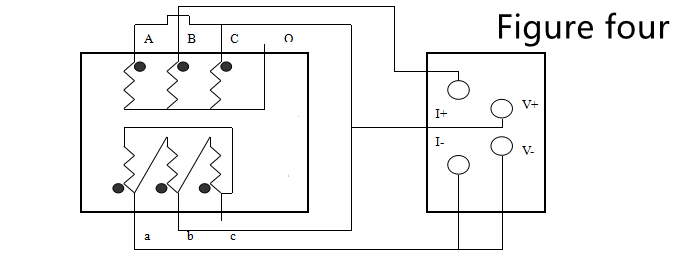

B. The wiring of the assisted magnetic method is shown in Figures 3 to 5 (applicable to Y(N)-d-11 connection group).

When measuring the low-voltage side of a large-capacity transformer, if the maximum current of the DC resistance tester is relatively small under existing conditions, or in order to speed up the measurement, you can choose the magnetic method to measure. In the following figure, Figure 3, Figure 4, Figure 5 are the wiring methods for measuring low voltage Rac, Rba, and Rcb respectively

2. Current selection: Turn on the power switch (I on the switch is on, O is off) and all current values will be displayed on the display. At this time, the preset current of the tested product can be selected through the selection key, and each time the selection key is pressed , The cursor will scroll between the current values of 10A, 20A, 40A, and 100A.

3. Test: When the current is selected, press the confirm key to start the test, and the meter will indicate the selected current value at the same time. After pressing the confirm button, the display shows “Charging”, and after a few seconds, it shows “Testing”, which means that the charging is complete. Enter the test state, a few seconds later, the measured resistance will be displayed.

4. After the test is completed, press the reset button, the power supply of the instrument will be disconnected from the winding, and the instrument will be discharged at the same time, the sound will alarm, and the ammeter will return to the zero position. At this time, the display screen returns to the initial state. After the second measurement or turn off the power supply, remove the test wire and the power wire to end the measurement.

Since the date of purchase of our company’s DC resistance tester, there will be technical personnel and video training on the test and operation methods of the DC resistance tester. Our company provides lifetime warranty and technical services for the whole machine. If you find any abnormalities or malfunctions in the DC resistance tester, please contact our company in time to arrange the most convenient solution for you.